Plastic injection trays use advanced injection molding technology to melt selected plastic raw materials at high temperatures and accurately inject them into carefully designed mold cavities. Under precise temperature and pressure control, the plastic rapidly cools and solidifies, forming a stable and precisely sized tray in one go. This process ensures uniform density and solid texture in all parts of the tray, greatly improving product quality and durability

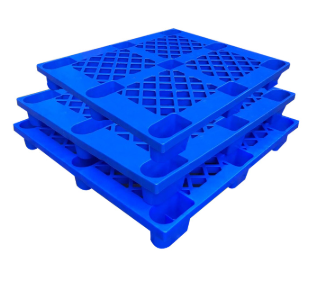

Rich surface design: The tray surface is divided into two main types: flat plate and grid. The flat surface is smooth and flat, providing good protection for the contact surface of goods, making it suitable for placing items with fragile surfaces or items that require tight fitting; Grid design enhances air circulation, has drainage advantages, and prevents moisture and heat accumulation in goods, especially suitable for the storage of environmentally sensitive goods such as food and agricultural products.

Reasonable fork height: The fork height is accurately calculated and designed to adapt to various types of forklifts, ground oxen, and other handling equipment, ensuring smooth connection between pallets and equipment during the handling process, improving handling efficiency and safety, and reducing the risk of operational errors.

High load-bearing capacity: Depending on the structure and material, the load-bearing capacity is excellent. Static load can reach 1-10 tons, which can stably support long-term stacking of goods; Dynamic load in the range of 0.5-1.5 tons, meeting the dynamic weight of goods during forklift handling; The overhead load is in the range of 0.3-1.2 tons, suitable for shelf storage scenarios, ensuring the safe and stable placement of goods in different states.

Stable temperature adaptability: It can maintain good physical properties within a wide temperature range of -35 ℃ to 40 ℃, without brittle cracking or deformation. Whether it is a cold storage environment or a hot outdoor site, it can function normally to ensure that the storage and transportation of goods are not affected by temperature interference.

Good impact resistance and wear resistance: It can effectively resist external impact during frequent handling and loading and unloading processes, and the surface is not easily damaged or dented. At the same time, it has excellent wear resistance, low long-term wear and tear, extends the service life of the tray, and reduces the cost of replacement for enterprises.

Safety and environmental protection features: no nails or spikes, avoiding accidental injuries to operators and goods; Non combustible, no static sparks generated, safe and reliable for use in flammable and explosive environments. The material is non-toxic and odorless, will not pollute the carrying goods, and can be recycled and reused, which conforms to the concept of environmental protection and helps the green development of enterprises.

Widely used in various industries such as chemical, petrochemical, food, aquatic products, feed, clothing, footwear, electronics, electrical appliances, ports, docks, catering, biomedicine, mechanical hardware, automotive manufacturing, petrochemicals, three-dimensional warehousing, logistics transportation, warehouse handling, storage shelves, automotive accessories, beer and beverage, textile printing, printing packaging, logistics centers, etc., to meet the diverse storage, handling and transportation needs of different industries.

Wen'an Qianhang Plastic Tray Co., Ltd

- Phone: +86 137-13722664999-4999

- Business Type: Manufacturer

- Location: China

- Main Products: plastic pallet

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: