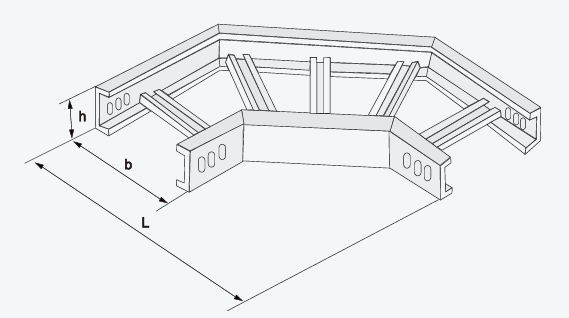

Cascaded horizontal bending Cable bridge frame

As a key component of the cable tray system, the cascade horizontal bending tray is designed to realize the horizontal steering of cables. Its unique cascade structure not only ensures the safety and orderly wiring of cables, but also takes into account the strength, heat dissipation and installation convenience of the bridge, and is widely used in cable laying projects in various buildings, industrial plants, data centers, power facilities and other places.

High strength and lightweight: The cascade structure ensures excellent load-bearing capacity of the bridge while achieving a lightweight design. Compared with the same specification of trough or pallet type tray, its weight can be reduced by about 20%-30%, which reduces the load-bearing requirements of building structures (such as ceilings and wall brackets) while meeting the needs of large-diameter and large-weight cable laying, reducing installation costs and potential safety hazards. At the same time, the lightweight characteristics also make transportation and handling more convenient and reduce transportation costs.

Excellent heat dissipation: The open cascade structure creates a good natural ventilation channel inside the tray, and the heat generated by the cable during operation can be quickly dissipated to the surrounding environment. After actual testing, compared with the closed bridge, the cascade horizontal bending bridge can reduce the operating temperature of the cable by 5°C-10°C, effectively slow down the aging rate of the cable insulation, extend the service life of the cable, and reduce the cable failure and maintenance cost caused by overheating.

Convenient installation and maintenance: The modular design concept runs through the product, the specifications of each component are unified, the versatility is strong, and the installation can be quickly completed by ordinary construction personnel without professional and complex tools. The cascade structure of the bridge makes the cable laying process clear at a glance, and the later maintenance personnel can directly observe the laying status of the cable, quickly check whether the cable is damaged, loose, overheated and other problems, without disassembling complex covers or shells, greatly saving maintenance time and labor costs.

Weather resistance and environmental adaptability: The product offers a variety of material options, including galvanized steel, stainless steel, aluminum alloy, etc. Galvanized steel is treated with hot-dip galvanizing or electro-galvanizing, forming a dense zinc layer on the surface, which has good anti-rust performance and is suitable for general indoor and mildly corrosive outdoor environments. Stainless steel materials (such as 304 and 316 stainless steel) can operate stably in strong corrosive environments such as humidity and chemical industry due to their excellent acid and alkali resistance and corrosion resistance. Aluminum alloy material combines the characteristics of light weight, high strength, and good weather resistance, and performs well in some places with strict weight restrictions and long-term outdoor use.

80 pcs in a carton

Hebei Kunyu Electric Co., Ltd

- Phone: +86 186-0120-9811

- Business Type: Manufacturer

- Location: China

- Main Products: Cable matching tray

- Total Employees:Less than 100 people

- Year Established:

- Export Markets:

- Total Annual Revenue: